Our History

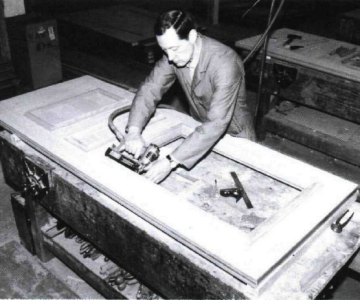

For nearly fifty years, Youngs Doors have been producing top quality high performance fire doors and doorsets to the construction industry. Originally the joinery shop of local building firm John Youngs Ltd, the company began to produce fire rated flush doors in the early seventies.

Success soon followed and the company began to specialise in door production and Youngs Doors was established as a stand alone business, exhibiting at Interbuild and other prestigious exhibitions.

The range of doors was developed over many years using independent fire test laboratories to establish design and performance parameters. Youngs Doors soon became a market leader in the field.

Today Youngs Doors moves forward with a continuing product development programme. From our purpose built state of the art production facility in the city of Norwich we can apply forty years of professional manufacturing expertise. We strive to deliver the best quality, easiest, correct, on-time and complete door-sets by offering a genuinely no-nonsense approach to help our customers achieve their goals any way we can.

ESTABLISHED IN 1985

1986

Youngs Doors became a Limited company in its own right and the final stags of the three-phase redevelopment of their Factory was completed. A new singlestory office accommodation was opened for the growing sales, administration and technical staff.

1986

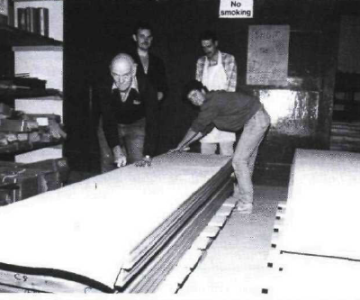

Sales network expanded and with the development of the factory increased production methods to be flexible, allowing for a virtually unlimited range of non-standard, flush doors, which could be produced in any size or thickness, in equal or unequal pairs, with glass or vent openings, to almost any finish. This adaptability led Youngs Doors to supply every major contractor in the United Kingdom.

1987

Providing for every national builder, Youngs Doors held a seminar to introduce its entire workforce to British Standard 5750. The recognised stamp of approval to denote overall quality assurance — a requirement increasingly being demanded by major commercial and public sector purchasers.

Its application is seen as a natural progression for Youngs Doors, in order to enhance an already high-quality product while also extending the area of potential supply.

1988

Doors were installed at Norwich Sport Village and a second opening with a sporting connection at a giant sports complex in Middlesborough, which called for seven sets of sliding doors. The design criteria laid down made it necessary to withstand the impact of two 15 stone men! To cushion any such collision, the doors have been faced with carpet material.

1989

Youngs Doors qualified for registration under the BS 5750 quality assurance scheme. Over stringent procedures for production control, work instructions and administrative practices were systematically put into operation and on 18th May, the approval of the British Standards Institution was given. To ensure that the required standards were maintained, daily checks were applied and ongoing review systems implemented. In addition, BSI inspectors monitored the scheme with periodic visits.

1990

Calls for the manufacture of some 50 flush doors of various types and to a high specification incorporating applied mouldings to create a panelled effect. Toughened fire-resistant glass was also being inserted in some leaves of the oak doors, which were destined for the new extension at the Sprowston Manor Hotel.

1993

Youngs Doors invested in a new multi-blade rip saw for their workshop, which quickly tackled a massive order for 1,000 doors for Sheffield City Polytechnic. The doors were for Shepherd Construction a Yorkshire based builder with whom Youngs Doors enjoyed a long working association.

The rip saw also proved that it is not all at sea when it comes to fulfilling contracts for the Navy. The Fasslane nuclear base in Scotland is one Royal Navy establishment that kept out the draughts with doors from Youngs Doors, while another was the sports hall at HMS Drake in Plymouth.

1999

Youngs Doors become sole supplier of laminate doors for all Tesco stores throughout the country. The contract involved the manufacture of about 800 doors a year for up to three years.

The company has made doors for a number of supermarket chains over the years, but never on this scale.

1999

Technology transformed production at Youngs Doors. Two vacuum lifts were installed to eliminate heavy manual work, speed production, and reduce costs. The vacuum lifts create a seal around the doors, enabling them to be lifted with ease from the factory floor to the workbenches.

1999

Norwich City Football Club saw the return of the Premier League after nine years, with the prestigious 8,000 seat South Stand opening up to thousands of people. Occupying more than 4,000sqm and stretching 21 metres to the top of its cantilever style roof, the new South Stand was the biggest building project at the club since construction of the Barclay Stand 10 years ago.

Youngs Doors won the contract to provide the fire-check doors.

2013

The successful construction of a new community centre in Sheringham, Norfolk by the R G Carter Group was completed in October 2013 as part of a wider scheme to bring a new Tesco Store into the local area.

Youngs Doors supplied multiple doorsets to this project.

2013

Almost 120 doors, in both four-panel and six-panel configurations, were produced for Help for Heroes’ new flagship recovery centre in Tedworth House, Wiltshire. Help for Heroes provides support for servicemen and women who have been wounded in current conflicts. By opening a new facility, the charity were able to accommodate up to 54 residents, as well as an additional 30 day visitors.

Each door had to be in keeping with the aesthetics of the Georgian stately home. Youngs Doors however, had to modify the design to ensure that the traditionally styled doors also met modern fire safety standards.

2014

For a number of years, Youngs Doors has provided made-to-order specialist door sets for the phased refurbishment of the James Paget University Hospital in Gorleston, Great Yarmouth.

Working closely with the hospital to minimise disruption, the team coordinated deliveries with tight construction programmes to allow the hospital to benefit from new facilities in the shortest possible period. To this end, door sets were supplied with frames and ironmongery installed to keep site fitting times to a minimum.

A selection of high performance door sets were supplied, from PVC faced doors specified for hygiene reasons, to specialist lead-lined doors and door frames for the Radiology Department – preventing the escape of X-Ray radiation.

2014

Youngs Doors joined the other Group Companies within R G Carter for the refurbishment project at County Hall, Norwich. Refurbishment works were all carried out whilst minimising the impact to Norfolk County Council staff and visitors who continue to occupy the building during the works.

Some of the refurbished floors adopted a completely open plan ‘hot desk’ approach, with oak doors sets and secondary joinery which we were pleased to have supplied.

2014

Youngs Doors supplied a total of 173 internal doors to the prestigious Westlegate Tower development in Norwich. The 11-storey building, completed in 1961 which stood unoccupied for many years, was structurally sound but due to floor-to ceiling heights of just 2.5m, it was unsuitable for revamping as contemporary offices and far more suited to reinvention as city-centre apartments.

A departure from our commercial contracts, this was a domestic project involving high-end flats and a penthouse over 14 floors. We provided a complete package of internal doors, frames and ironmongery including hinges, locks, handles and suited keys as well as quality oak doors and frames.

Due to the limited space on site, the door frames were provided first. Once these were installed the doors were delivered in phases, a mixture of 1 hour and ½ hour fire rated doors, along with some 35 decibel sound reducing doors.

2015 – 2016

Youngs Doors provided the doors for the Next Store at Longwater Norwich, making 45 complete internal door sets in black walnut with vision panels.

We look forward to continuing working with Next as their preferred supplier, having established and maintaining the relationship with Next. This meant that we will be supplying more doorsets to all new stores over the country, as far as Scotland and Northern Ireland.

2017

This year, it became possible to be able to manufacture in-house PVC encapsulated door sets which when used in conjunction with beadless triple glazed units, give a hygienic flush appearance. The doors which are available in various colours provide impact protection in any environment and hygienic cladding which is of course crucial in a cleanroom environment for many sectors including healthcare, food and leisure and offer both 30 and 60 minutes fire protection and laser protection. The vision panels are a triple glazed unit that can be offered as clear glass or with an integrated blind are also manufactured at Youngs Doors.

The new door sets were recently installed at Springfield Hospital in Chelmsford for R G Carter Southern as seen in the picture.

2018

Youngs Doors supplied the doorsets for the new commercial office building, knows as Incubator 2 in the heart of the Alconbury Weald Enterprise Campus, in June.

The office space is spread over two floors, built using steel frame construction which is be exposed internally in line with the industrial design concept that the interior is based upon, with a strong feature glazed elevation facing the Boulevard. The external facade includes larch cladding and single-ply roof.

2019

Youngs Doors provided doors to the new Lime Academy in Parnwell, Peterborough, which was officially opened by the CEO of the Lime Trust, Lynne Harrowell and Christopher Cole. Much to everyone’s delight.

The new building included the addition of a multiuse games area and a two-storey extension to

the existing school. The extension features four new classrooms, each with a Smart TV.

2020

Youngs Doors were pleased to be able to help in an urgent request for double door sets needed at the local Colman Hospital in Norwich.

The doors were needed to help the NHS adapt facilities to deal with COVID-19, and safely segregate suspected/confirmed cases of Coronavirus. We were able to turn the MJS Projects 2no FD30 sets around in just two days, and supplied them direct to the hospital ready for installation.

The staff were incredibly happy with the door sets, so much so, a further set was ordered and was supplied to the hospital in another quick turnaround.

2021

Its always great to be part of a project that supports the next generation. Youngs Doors manufactured and supplied 67 internal door sets at the Digi-Tech Factory at City College, Norwich.

Painted on site in a bright yellow accent, they are striking against the white interiors and gives an industrial appearance. Featuring exposed soffits and services allowed flexibility for future modifications and to reflect the narrative of a ‘Digital Experience’. Our doors certainly give that bright modern feel we are sure the students love!

For more information on this project visit https://lnkd.in/ecgxb4DH

2022

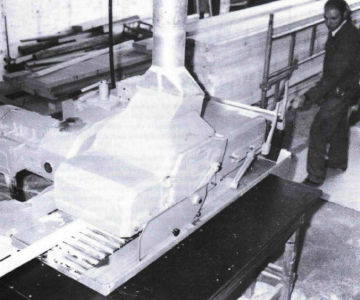

The last few years has seen in high demand for our products, in particular Fire Doors. With this, it meant for the need to invest in new machinery to ensure we continue to keep up with the industry, ever increasing client orders and continue to deliver the high quality finishes required.

We have recently seen the installation of a new Edge Bander to replace the old machine, which had been in place for 22 years. We are extremely pleased with its performance; the new machine runs at 18 metres per minute vs six metres previously. Its impressive finishing quality has also reduced re-work and created less work further down the process.

The old Edge Bander was the very first machine John Kemble (left) worked on for the company 11 years ago, and now he and Scott Winton (right) can be seen here operating the new machine – they are certainly are not missing its predecessor!